Few components of a modern sailing yacht have more influence on sailing performance than the keel. In this article, we describe the design process for our latest keel design: the keel for Project Ouzel. You can get an idea of the yacht at our project page.

The seed of any keel geometry starts very early in the yacht’s design process—particularly for a world cruising yacht—when a decision is made about draft. This decision, as in the case for much of yacht design, comes down to a trade-off: draft is almost always better for performance, but needs to be balanced with the practical concern that comes with a deep keel. Will the yacht have access to anchorages, moorings, and harbors in the chosen cruising grounds? Different clients have different interests, and for Project Ouzel a decision was made to explore this trade-off in more detail.

For a naval architect, draft is a magic variable: Increasing draft almost always makes things better, within reason. A deeper keel typically means it will be more effective at creating lift—which means we need less keel area. It also means it will be more efficient, creating less drag for the same amount of lift. It enables lower ballast, generating more righting moment. That can enable a larger sail plan, or for the same sail plan, a lighter keel—again, going the right way for performance. There are engineering limits that can make things harder, but overall, more draft means a faster boat.

For the Ouzel project, we converged towards a draft of 12 feet after exploring the design space. A little more than the typical cruising yacht of this length (95 feet), but well under what can be found on the racing circuit. The idea of a lifting keel was discussed but quickly dismissed: the benefits weren’t worth the risks that come from another highly loaded mechanical system.

Once the draft was set, we determined the other principal parameters of the design: the sail plan and the target righting moment.

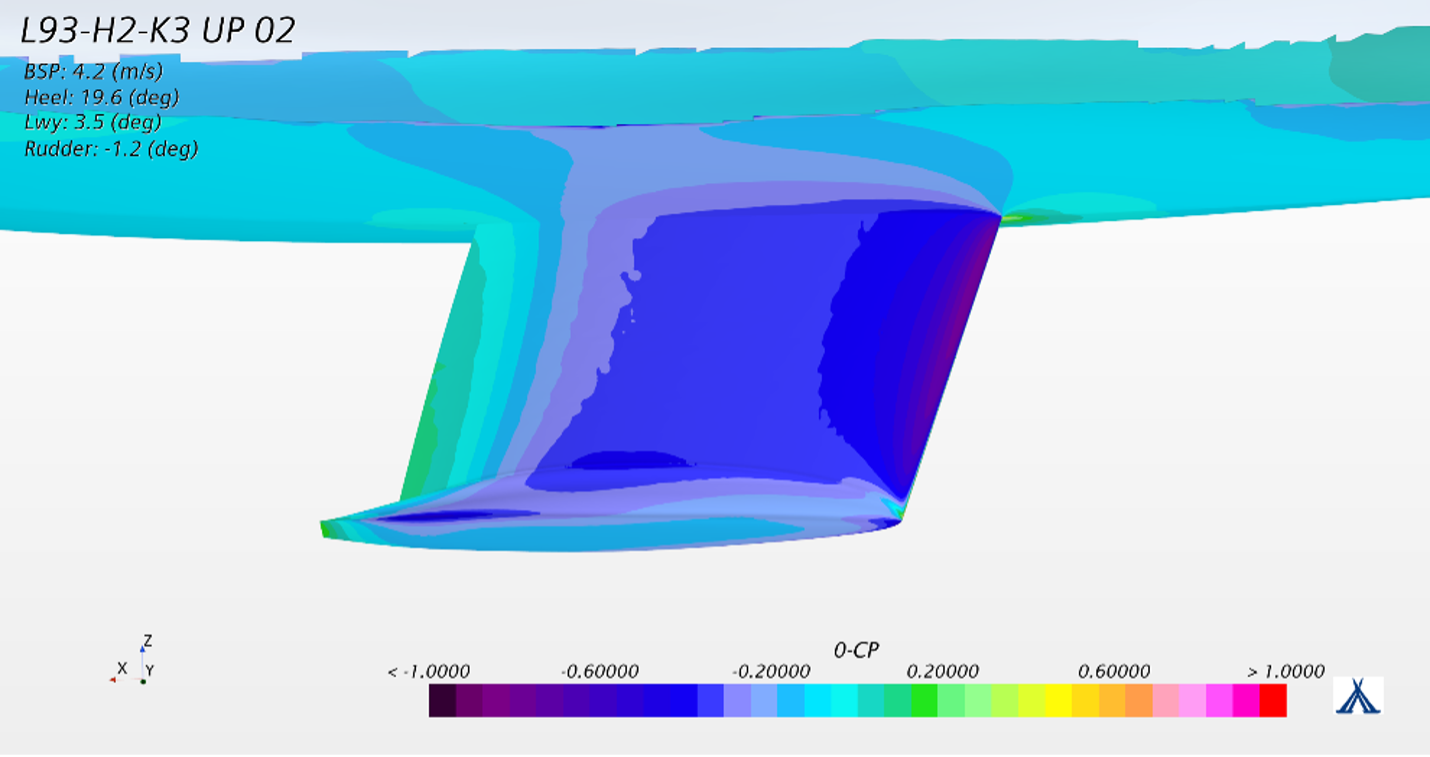

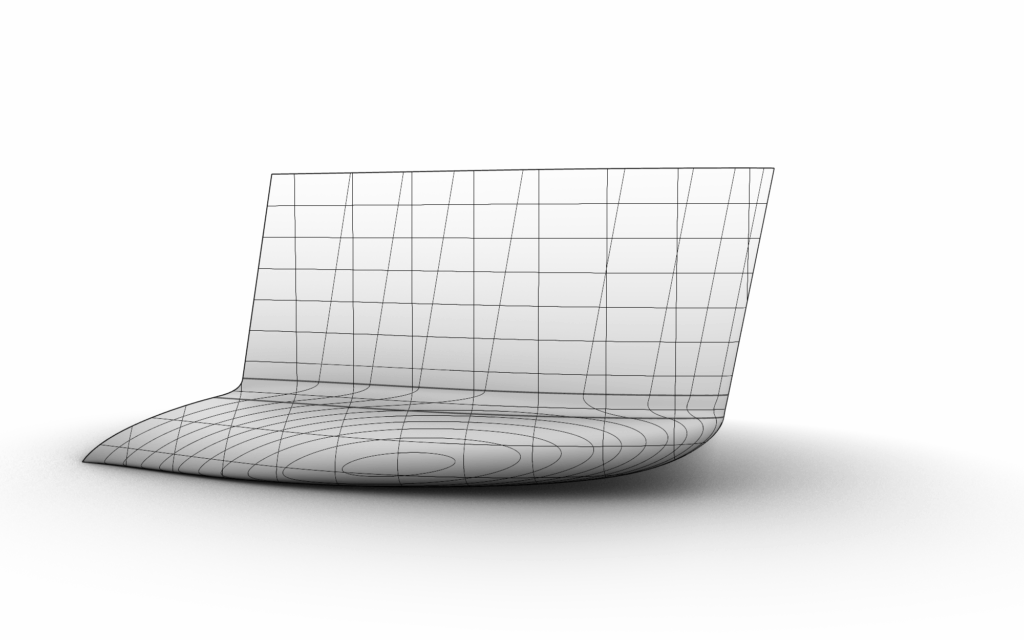

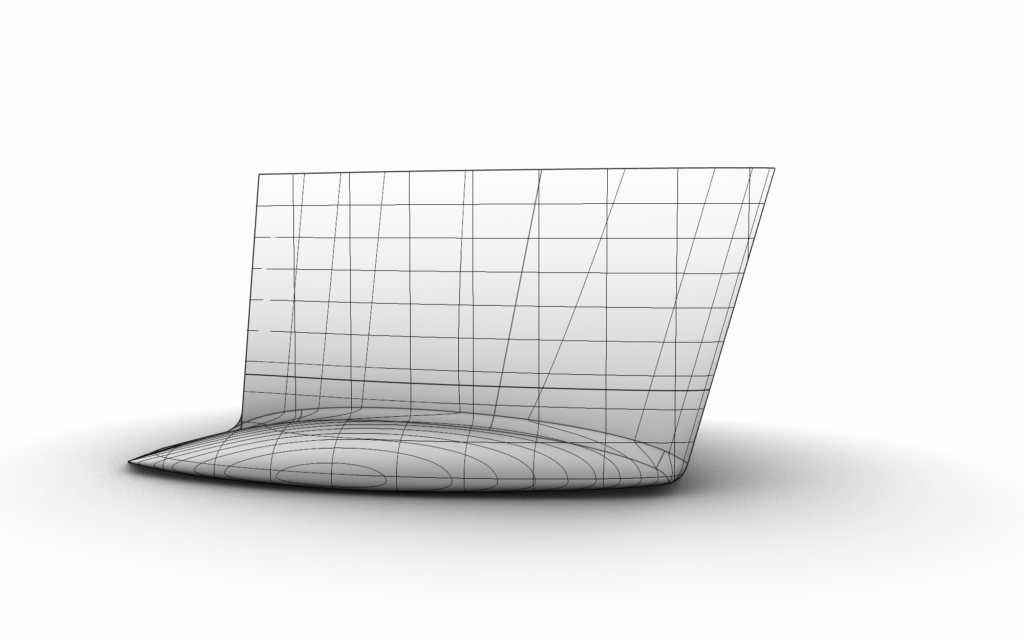

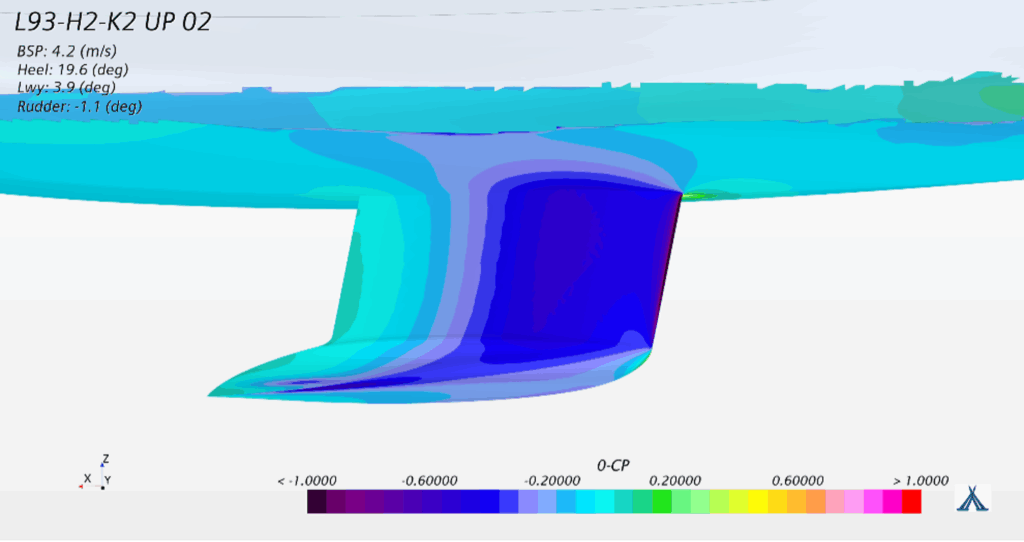

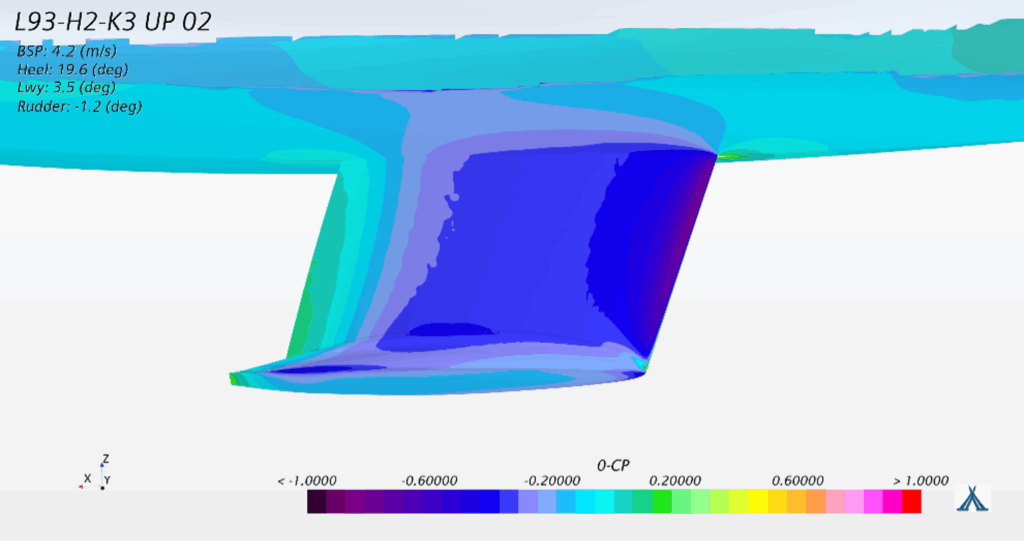

Most naval architecture offices have a few standard keel designs they can use, but for the Ouzel project our client wanted to push the design further and explore a few options to extract more performance. This led to a series of designs that converged to two distinct approaches—a blended approach in which the keel bulb and keel fin are blended together in one sculpted surface, and a more conventional fin & bulb approach in which the fin and bulb are more distinct elements. To understand which keel would work best, we worked with our friends at KND Marine on one of the shapes and had them run some CFD calculations to understand the performance characteristics of each keel. They used this data as input to a custom velocity prediction program (VPP) to estimate the real-world impact of these two keels.

The immediate take-way from the comparison of these two optimized solutions was although the pressure distributions look quite different, their performance was incredibly close, with a very minor advantage to the Fin + Bulb geometry—on the order of less than a second per mile. This made the decision tricky and opened consideration for a few other criteria.

Although this is a yacht designed for cruising, our clients are experienced sailors with an interest in racing, and there was some discussion of perhaps entering a few low-key races. This interest led to us ask ourselves if we might learn something by running the two configurations through a rating rule velocity prediction program (VPP)—in this case the ORC VPP.

What we learned was interesting: the VPP, which is based on a large dataset of designs, thought the blended geometry would be faster—on the order of 2 seconds per mile. These rating rule VPPs are quite good at establishing general performance, but they don’t take into consideration smaller optimizations in shape. So even though the rating rule VPP felt the blended version was faster, we remained confident that the other version was just as good, and probably a tad better.

Finally, we also asked the potential fabricators of the keel for their opinion, and they all felt the Fin + Bulb version would be simpler to make.

Armed with this information, our client made the decision to go with the Fin + Bulb geometry. And if the yacht races under the ORC rating rule, it won’t suffer from the 2 seconds per mile penalty that would have resulted from the other keel.

In part 2, we detail the engineering and fabrication. Read A Performance Cruising Keel – Part 2: Engineering and Production

For more information, visit the Project Ouzel design page.

A joint venture of Rockport Marine, Langan Design Partners, Mark Whiteley Design, and Marine Construction Management (MCM), Project Ouzel is scheduled for launch in late summer 2025.