Once the keel shape for the 95-foot sloop, Project Ouzel, was determined in the concept stage (see A Performance Cruising Keel – Part 1), the engineering of the keel could begin.

The choice of materials was relatively straightforward, as this is a cruising yacht. Toughness, simplicity and common sense dictated the materials.

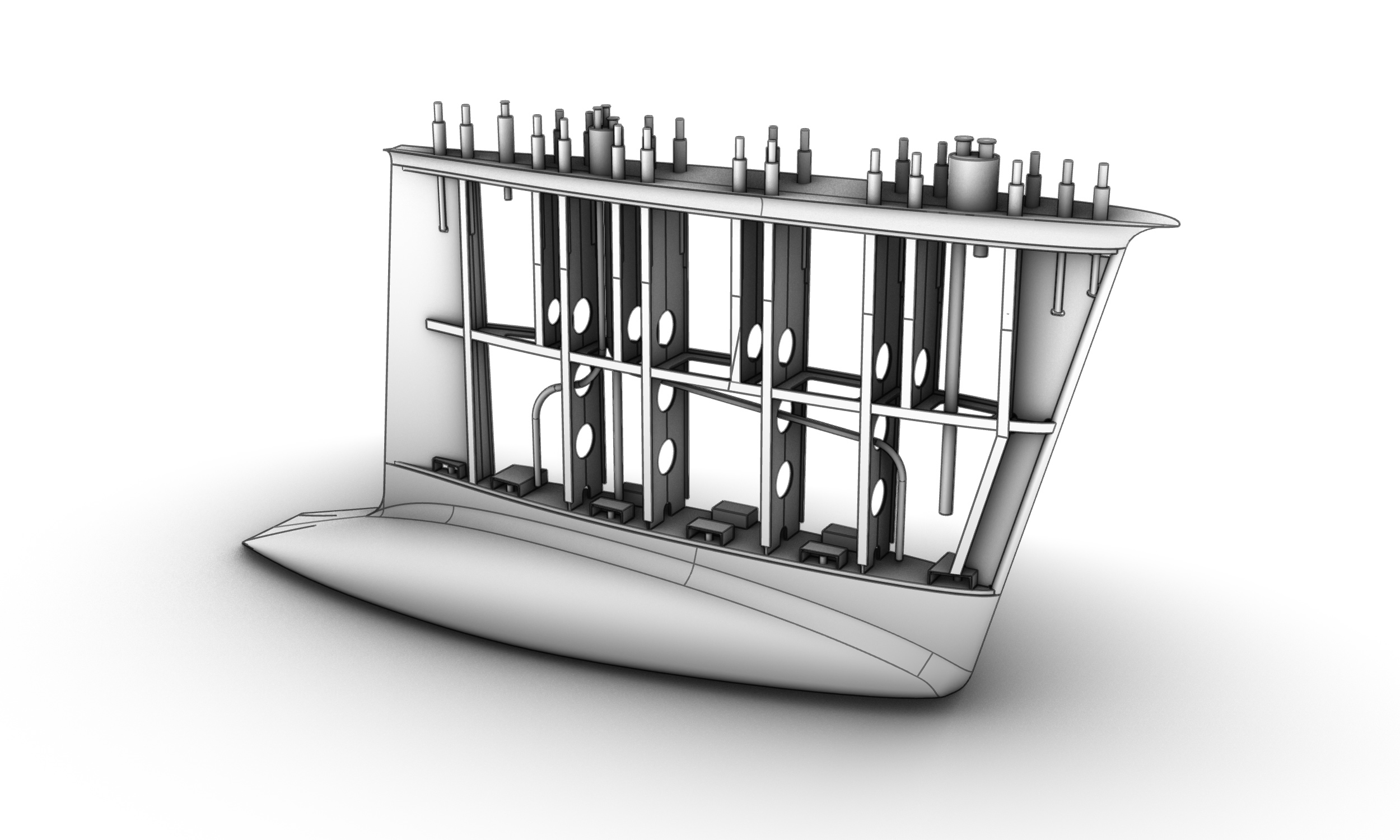

The fin portion of the keel was engineered to be built in steel. Although fiberglass was considered, the geometry of this keel lent itself well to a steel approach.

Due to this keel’s relatively large size, we opted to use the fin portion of the keel as an additional tank to store fuel for long passages. This led to some interesting plumbing considerations to ensure proper function, and considerable thought went into how to inspect and clean the tank at regular intervals.

The bulb is a lead casting with around 2 percent antimony for stiffness. The shape was provided to the foundry in a digital 3D format, which they used to create a pattern. From this pattern they created a sand mold, in which they poured the lead.

The keel bolts were specified as high-alloy steel for their material properties—they need to accommodate the sailing loads for the life of the yacht—and the much rarer, but greater shock loads in case of a hard grounding. The bolts are about 26 inches long. They are welded to the structure of the keel fin and tied into the structure of the boat using high strength nuts.

The keel elements were built and assembled by Irons Brothers, in the UK.

The keel arrived at Rockport Marine during the winter and is patiently waiting for the hull to come out of the shed later this summer.

For more information, visit the Project Ouzel design page.

A joint venture of Rockport Marine, Langan Design Partners, Mark Whiteley Design, and Marine Construction Management (MCM), Project Ouzel is scheduled for launch in September 2025.