Out of Sight: Stabilizers Add Onboard Comfort

Two recent stabilizer refits—one power, one sail—have more in common than you might think

If stabilizers do their work while out of sight underwater, will anyone notice? The answer is definitely yes—at least according to two of our clients. Recently we were involved with a pair of successful refits to improve the stabilization of two very different vessels: a semi-displacement motor yacht and a large sailboat. Comparing the two jobs helps explain why stabilizers have become such a must-have item—and reveals the value of our collaborative approach to complicated projects.

Why add stabilizers?

Stabilizers improve onboard comfort by reducing a yacht’s rolling motion. While gyroscopes have recently become very popular and can be an excellent approach for some vessels, both our refits ended up with active-fin type stabilizers. Gyros and fins work very differently, but they achieve the same goal: to reduce the roll motion and make being on board more comfortable, both underway and at anchor.

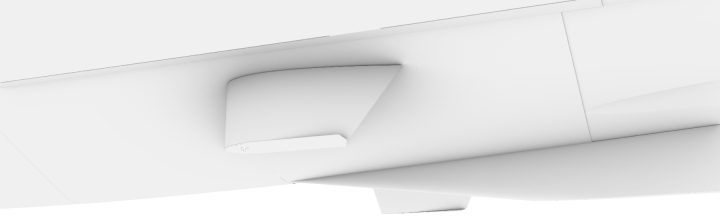

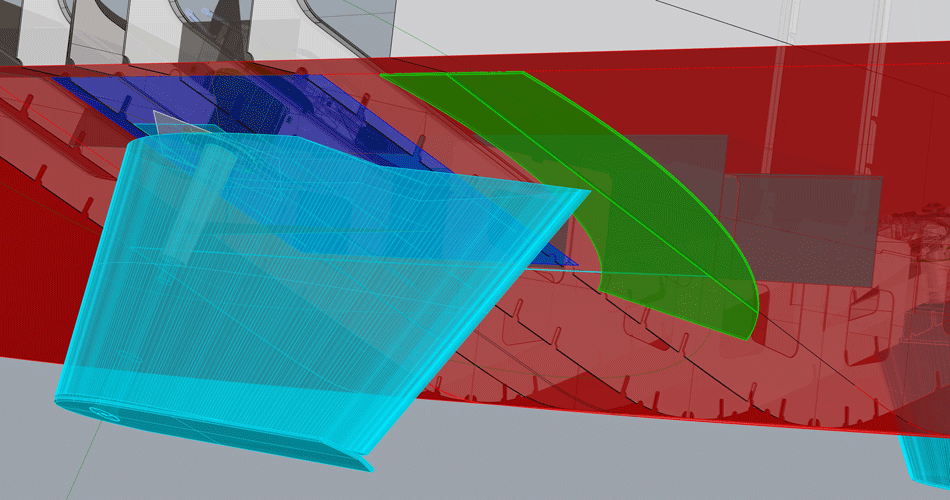

Fin stabilizers look like a pair of rudders, angling out from under the hull on either side. Their rotation is governed by computer software that controls a pair of hydraulic rams inside the hull. The fins can respond to the yacht’s motions, and their angle is adjusted in real-time to minimize roll.

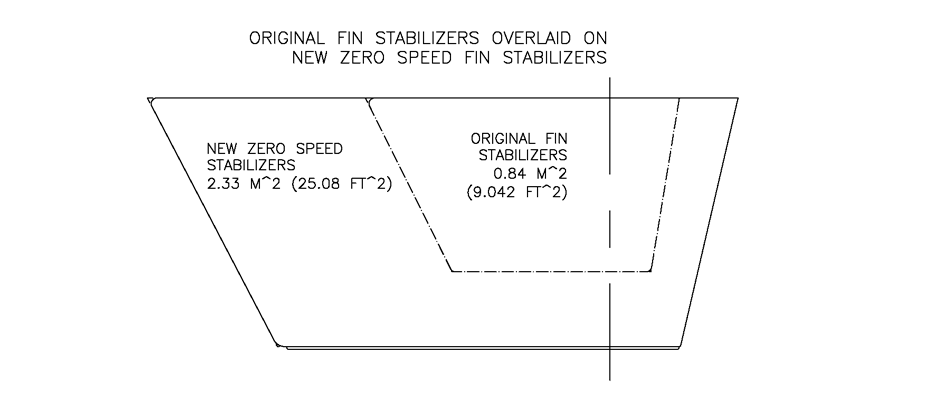

While underway, water passing over angled fins can develop large forces, so smaller fins are typically quite effective. Once the boat stops moving, however, bigger fins are needed to achieve “zero-speed” stabilization. In that scenario, the fins behave more like large paddles, pushing on the water to keep the boat steady. For this to work, they need to be quite large.

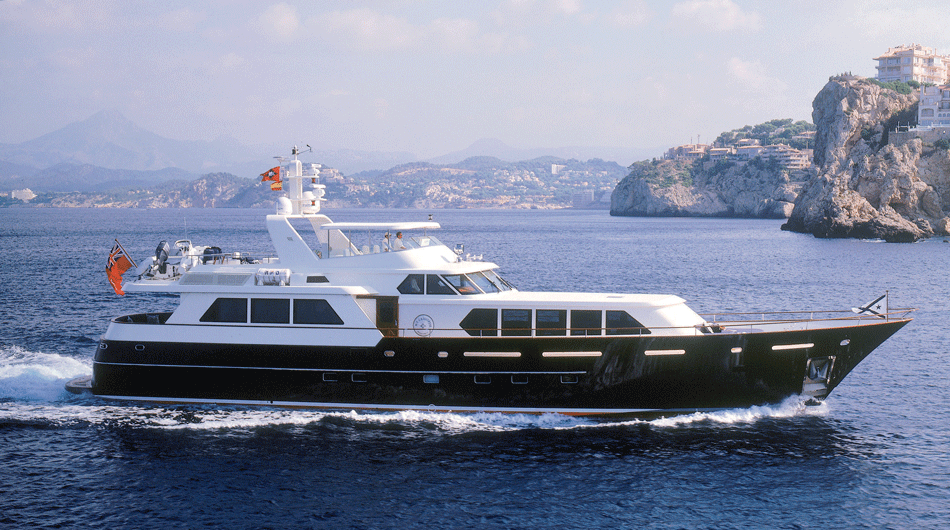

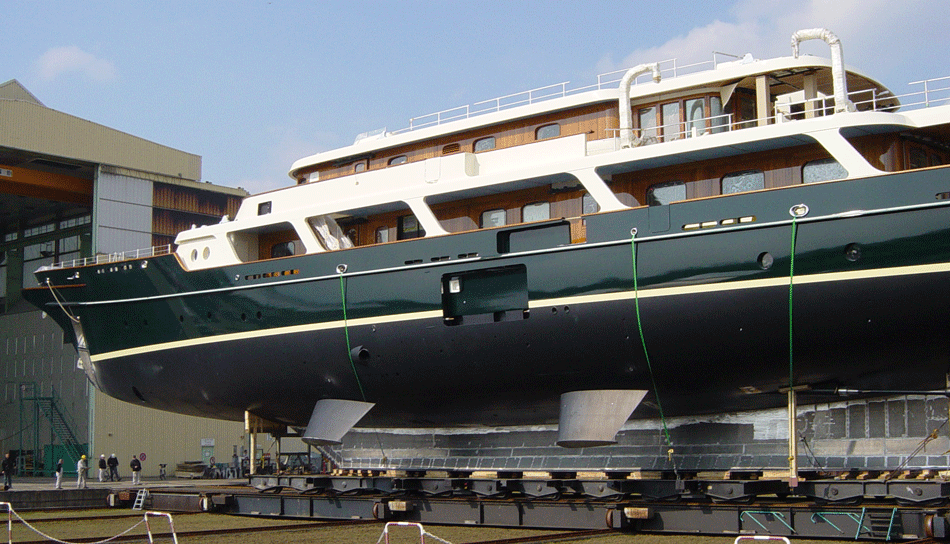

Stabilizer Refit #1: ANJILIS (ex – CASSIOPEIA)

Anjilis was designed by Langan Design and delivered in 2004 as Cassiopeia. When the yacht changed hands in 2020, the new owners wanted additional roll dampening at anchor, and their project manager contacted us. We initially considered adding one or two gyroscopes but could not find adequate space in the yacht to fit the equipment and accommodate the increased electrical loads.

The solution was to replace the existing fins with new, larger ones almost three times the size. The challenge was to fit the larger actuating mechanism and the required supporting structure under the port and starboard guest cabins.

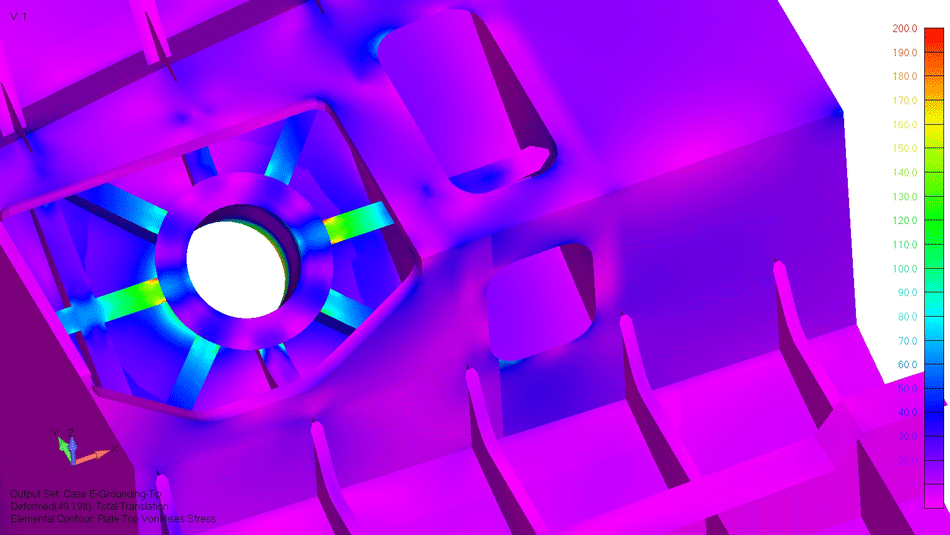

It was quickly apparent that reinforcing the existing structure wasn’t practical, so the team decided to cut out the aluminum structure and weld in a new foundation. In close collaboration with our preferred structural engineer, we designed a new structure that was up to the task. Using Finite Element Analysis (FEA), we validated the design to verify it could sustain the substantial loads generated during everyday service and in the exceptional case of grounding. (As an aside, the fins are designed to snap off in the grounding case, preventing damage to the yacht’s structural integrity.)

The new actuating mechanism was both taller and wider than the original units. Still, we minimized the impact on the yacht’s interior by aligning the units fore and aft and designing the structure accordingly. In the end, we only had to raise the outboard cabin sole by a couple of inches.

The shipyard completed its work in August of 2021, and the sea trials demonstrated that the new stabilizers are a significant improvement. Our client is delighted.

Fun projects sometimes come in pairs, and we were able to apply what we’d learned to our very next stabilizer refit—proof that motor yachts and sailing boats do have something in common after all.

Stabilizer Refit #2: KAORI

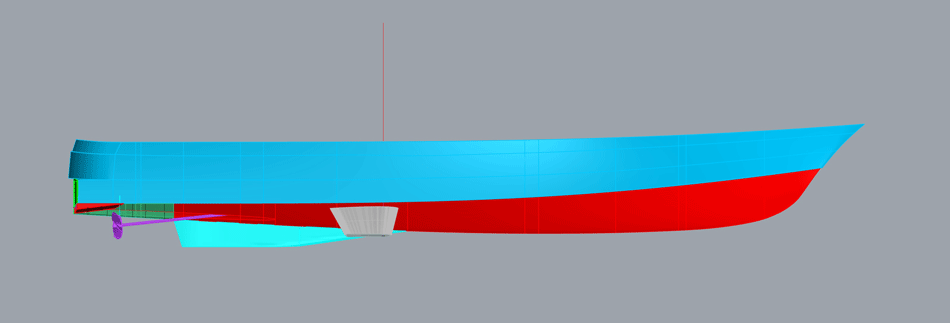

Originally built in 1992 as Mandalay, Kaori has had several upgrades over the years. Her current owner came to us convinced that stabilizers could reduce the discomfort of open-water passages, especially since the yacht does a lot of miles under power in the Pacific Northwest. Again, the first challenge was to identify what technology to use. Gyros were considered early on but quickly set aside as impractical for Kaori. Active fins were the obvious choice, but that left the question of where to place them: the engine room was already chock-full of other systems. It took some creative thinking from all involved and some serious shipbuilding expertise for the shipyard to sign on to the solution: we could create two small water-tight compartments in the engine room by taking over a couple of tank bays.

It is somewhat rare to see sailboats fitted with stabilizers. Sailboat motions are dampened by aerodynamic and hydrodynamic forces, which tend to reduce the rolling motions. Still, this isn’t the first time Langan Design was asked to consider this option: S/Y Eos, Langan Design #25, is a 300-foot three-masted schooner that has not one but two pairs of stabilizers. This configuration was tank-tested to prove that the benefits were worth the extra drag and that the potential drawbacks could be handled. Of particular concern was ensuring that these large appendages could be properly oriented while sailing, to prevent them from negatively affecting the balance of the boat. In fact, we found that when tuned properly, the fins can improve the sailing performance on some points of sail. The result was a close collaboration with Naiad, the supplier of the stabilizer equipment: they added a “sailing” mode to their control system, starting with Eos. The plan is to use this same control system on Kaori.

Working with the same engineer, we developed Kaori’s general structural arrangement and fine-tuned plate thicknesses and details based on the results of an FEA analysis.

The image above shows the first run of the FEA study. The areas in yellow and red highlight the areas of highest load, in this instance in the case of a grounding. The structure was optimized and reinforced locally to carry these loads safely.

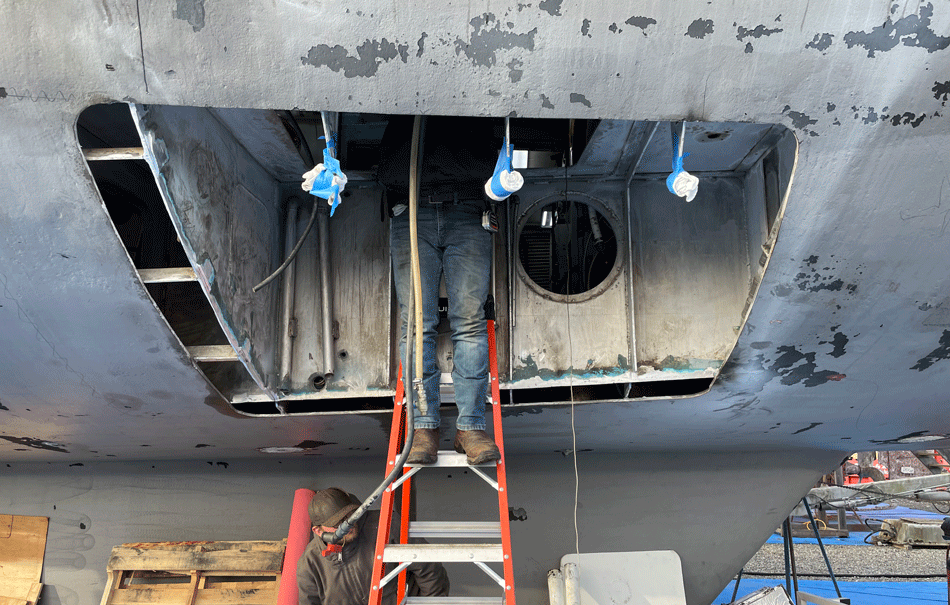

Once we validated the design using FEA, the shipyard went to work. They started by cutting into the side plating and removing all the structural elements that needed to be replaced. They also used the two gaping holes in the hull to remove some engine room equipment due for an upgrade. Perfect time to do so!

The new structure was added in, and a thicker insert plate was installed around the foundation of the units.

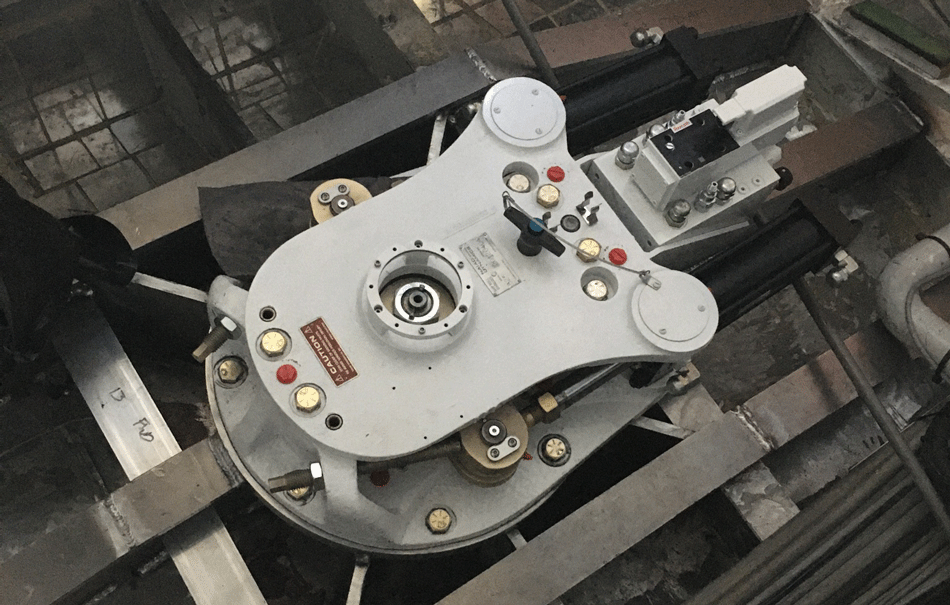

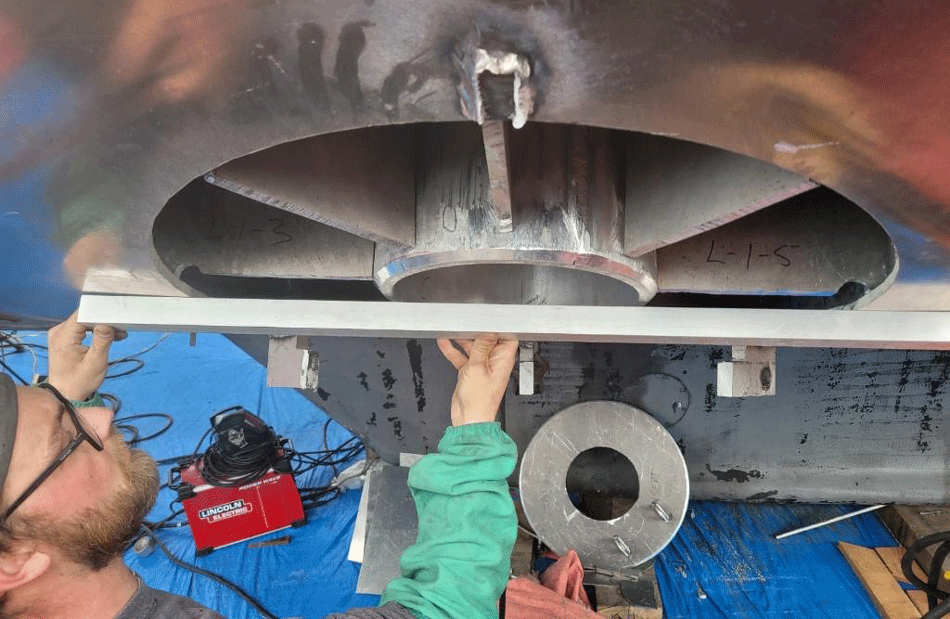

Once the supporting structure was welded to the inside of the new hull structure and checked for fairness, the stabilizer’s foundation tube could be carefully installed.

The refit was completed in December of 2021, and Kaori’s owners report that the system works great—when motoring, sailing, and at rest in a remote anchorage.

These two refit projects taught us that with a collaborative approach, carefully thought-out upgrades can happen even when space is limited. They also reminded us—twice—that stabilizers make a noticeable improvement to the onboard experience on a wide variety of vessels, even though they do all of their work well out of sight.

For more information, contact us